During our Shenzhen business trip, we also took time to visit Refond Optoelectronics, a new DVN member this year. They exhibited at the Munich and Cologne DVN events this year, and will exhibit in Tokyo next month.

I decided to focus my article on their miniLED products, as Refond are a miniLED pioneer and they are delivering one of the first miniLED rear lamps in production in China for the Great Wall SAR: RGB tri-colour red LEDs with 0.92-mm pitch. LVDS data transmission is used to drive each LED pixel, with CAN and Ethernet options.

Refond were established in 2000 in Shenzhen. There are more than 2,000 employees, of whom 800 are in Shenzhen.

Their first automotive LED delivery was to Hyundai in 2007; now automotive business represents around 30 per cent of the company’s global revenue. R&D represents between 6 and 8% of the global revenue.

Refond Optoelectronics has accumulated over eight years of expertise in the field. Since initiating Mini LED technology development in 2016, the company has achieved several industry milestones.

In 2016, Refond developed the first Mini LED product in China, and in 2017, established the country’s first Mini LED production line. It was also the first in China to achieve mass production of Mini LED backlight products using COB (Chip-on-Board) packaging technology, filling a key technological gap in small-pitch LED display solutions. These products have since been widely adopted by several leading Mini LED TV brands, gaining significant market recognition.

Refond have continued to build robust technological barriers, owning more than 100 IP rights in the miniLED field. The company have mastered key core technologies including COB architecture, flip-chip bonding, molded encapsulation, light uniformity optimization, ultrathin structures, high-brightness solutions, driver hardware and software design, and cost optimization. These advancements have significantly contributed to the development of China’s ultra-high-definition (UHD) display industry.

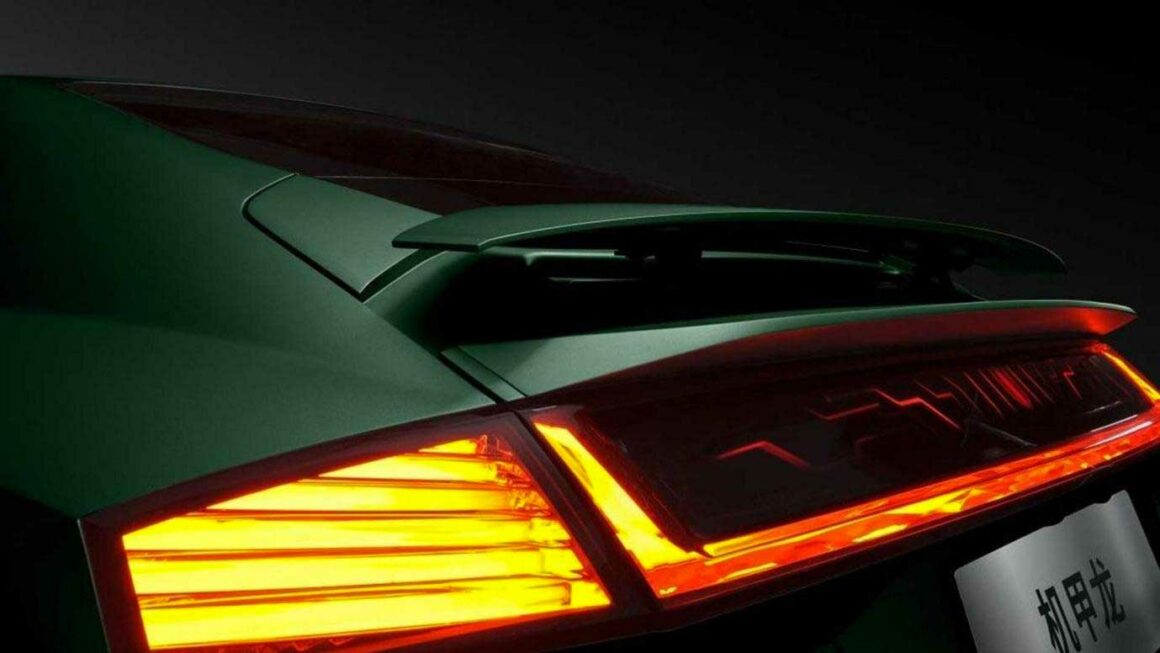

For vehicle lighting application, Refond are presently delivering their MiniLED RGB Tri-Color product, with 0.92-mm pitch and 2.3-kilonit luminance. The module is 75W × 92H mm, and quite thin. At DVN Munich, Refond demonstrated products with RGB COB LEDs, 0.68-mm pitch, and 2-kilonit luminance — the technology can achieve 30 kilonits. This miniLED dynamic car logo enables dynamic display effects by precisely controlling the brightness, colour, and flash frequency of each LED chip. It can display text, graphics, animations, and other information — attracting attention, facilitating vehicle recognition, and enabling new aesthetics.

Refond operate three major production facilities in Shenzhen, Hubei, and Zhejiang. Through lean management across the production process, the company have established precise, flexible, intelligent digital workshops, with multiple dedicated miniLED production lines and a complete process control system.

During our DVN visit, we talked about the challenges in mass-marketing miniLED applications.

Automakers want finer pitch, that’s one of them. Currently, Refond can mass produce minimum pixel pitch of 0.39 mm for RGB, and 0.2mm for monochrome. The main technical challenges for pitch reduction are efficiency and yield bottlenecks of mass transfer, inspection, and repair. There’s also a cost challenge.

The second challenge is the shape of the PCB—flat, flexible, or curved. As the display pitch decreases, the number of PCB layers must increase, making it difficult to achieve flexibility in small-pitch displays. The finest flexible-display pitch achieved by Refond is 0.68 mm.

The third challenge is the signal transmission and control. As the pixel count increases, the complexity of signal transmission and control escalates rapidly, necessitating a new E/E architecture for resolution. Refond continues to collaborate closely with partners to address this challenge.

In the automotive exterior display application, the POB (Package on Board) and Mini COB (Chip on Board) solutions coexist in the market. Refond has achieved mass production for both solutions. Refond’s Mini COB solutions focus on small pixel application (pitch less than 2.5mm), POB solution focus on pixel pitch more than 2.5mm application.