Horizontal headlamp aiming in North America, with SAE beams, is one of the most nuanced challenges vehicle lighting engineers face. In the latest update to their IntelliAim platform, Dajac have introduced a feature that tackles the complexity of horizontal aiming, bringing new levels of precision, flexibility, and traceability to the manufacturing process.

Unlike vertical aim, wherein the beam pattern offers a defined, predictable visual cue — the cutoff — there are no such indicia for horizontal aim defined in the U.S. SAE lower beams often lack a defined reference point suitable for use as a horizontal aiming cue, and if they exist, their position is not consistent across all beams.

Simulation work by NHTSA has shown that as little as 0.5 degrees of horizontal misaim can reduce pedestrian detection distance by about 25 per cent. Automakers’ own research has shown that horizontal aim can make the difference between a “good” headlight rating and a “poor” one on the IIHS tests. And IIHS, for their part, have found that the horizontal aim on new cars is not necessarily where it should be. For automakers and tier-1 suppliers, achieving accurate aim isn’t just about regulatory compliance—it’s a matter of safety, IIHS ratings, and user experience.

The push to improve horizontal aim stemmed from limitations encountered in real-world lamps. Dajac’s existing V/O+ software already excelled at locating the cutoff elbow, if it exists, but beam patterns with a flat-across cutoff or a dip in light just before the elbow posed issues. The fix comes in the form of several key software upgrades:

- Customizable Scan Start: Operators can now choose where the horizontal scan begins. This is critical for lamps with cutoffs or notches that can serve as reliable aim points, while avoiding oddities in the beam pattern or slight tilt that might otherwise mislead the system.

- Scan Thresholds: Horizontal and vertical scans now use separate thresholds. Previously, only vertical threshold existed.

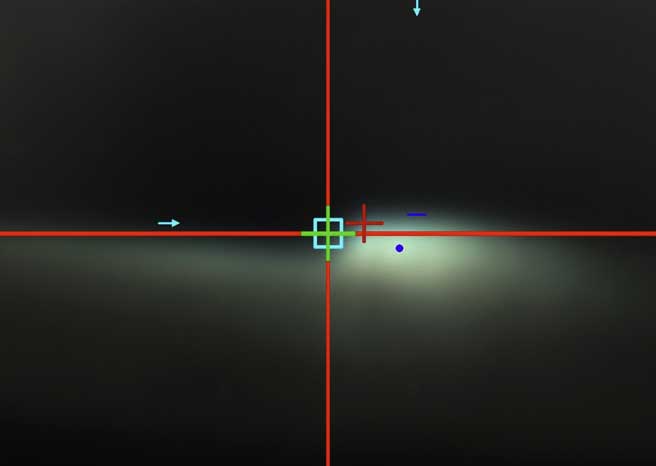

- Visual Feedback: The software now displays scan lines and markers—including the hot zone, cutoff, and start position—using clear visual on-screen ‘decorations’ to support easy verification and adjustment. These changes were built as an extension of Dajac’s existing V/O+ logic, maintaining continuity while adding major improvements

With these enhancements, Dajac’s Osprey systems with IntelliAim — especially those paired with the Expert I/O 1000 — are delivering better precision and repeatability than ever before. That translates directly into less rework, fewer misaimed lamps, and greater compliance confidence. Dajac’s EU-compliant traceability database ensures that every aim is recorded and auditable, making it easy for manufacturers to meet strict international regulations.

While the technology behind the update is sophisticated, its impact on the production floor is intentionally simple. Operators can easily configure and fine-tune it to the needs of each lamp. Whether the system is working with sharp cutoffs, softer beam patterns, or lamps designed specifically to meet IIHS criteria, the new horizontal aiming feature adapts. Importantly, it also supports relative aiming of multi-beam configurations—critical for today’s complex lighting systems. And if a lamp introduces a third adjuster, IntelliAim handles it seamlessly through Dajac’s robust hardware integration

The algorithms powering horizontal aiming will also help identify ADB shadows and support edge detection in digital lighting systems.